The best welding techniques forreliable and safe networks

Bestoplast has a welding workshop that allows us to make the connections of special HDPE parts that cannot be obtained directly by injection in one piece. Two welding techniques are available to our customers to ensure the reliability and safety of the networks: butt welding and electro-welding with electro-weldable sleeves.

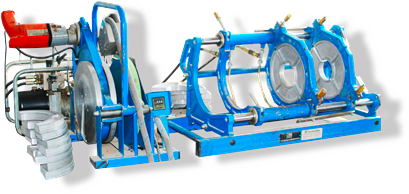

Butt welding

Butt welding is a technique for joining thermoplastics by melting the ends of two tubular elements by means of a hot plate. The assembly is carried out by performing the following operations :

Butt welding requires two conditions :

The pipes must have the samediameter and the same thickness

The butt-welding machine shall comply with the standard

ISO 12176-1

| Range of machines | |

|---|---|

| Type of machine | Welded diameters |

| Machine DN 250 | ∅ 250 au ∅ 90 |

| Machine DN 315 | ∅ 315 au ∅ 125 |

| Machine DN 500 | ∅ 500 au ∅ 250 |

| Machine DN 630 | ∅ 630 au ∅ 315 |

Electro welding

The PE connector is equipped with an electrical winding integrated during manufacture. The voltage is applied to the terminals of the fitting, the dissipation of the electrical power by Joule effect causes a fusion of the surfaces of the two parts to be joined. An intimate mixture between the HDPE of two pipes and the fitting ensures cohesion and perfect sealing between the fitting and the pipe.

| Reference standard | Range of welded diameters (mm) | Operating temperature (°C) |

|---|---|---|

| ISO 12176-2 | du 20 au 630 | -10 à +45 |