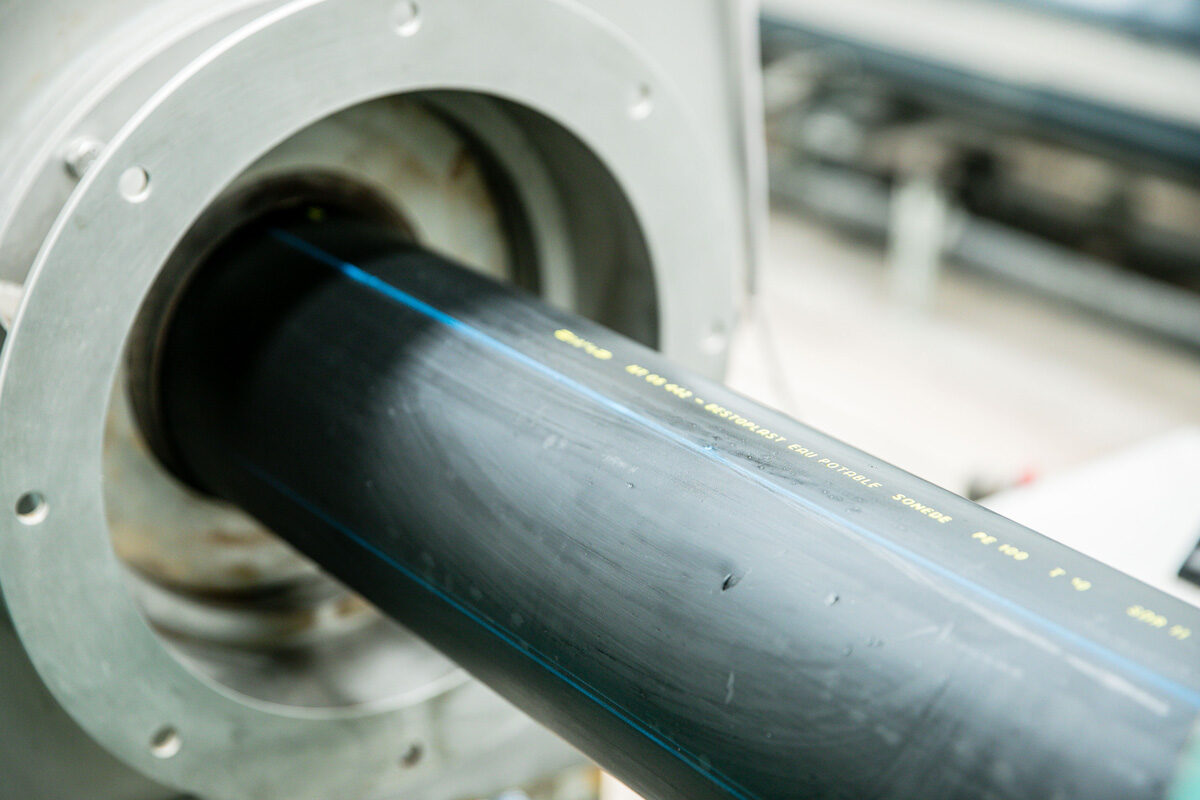

HDPE 100 or PE 80 pipes for drinking water and sewage

Bestoplast high density polyethylene pipe (PE100 or PE 80) is corrosion resistant, has excellent chemical resistance and does not favour bacterial growth; it is light, flexible, easy to install and especially to weld; and its organoleptic properties guarantee the preservation of water quality.

lifetime

POLYETHYLENE RESIN

Nominal pressure

The Bestoplast HDPE pipe complies with the NT 05 442 – or EN 12 201 Part 2 standard.

Bestoplast HDPE pipes can be joined by welding using the electrofusion technique (electrofusion fittings) or the butt welding technique.

The high density polyethylene pipe (PE100 or PE 80) is manufactured from resins stabilized against ultraviolet rays and conforms to the requirements specified in the Tunisian standard NT 05 441 or the standard EN 12 201 – Part 1 relating to polyethylene (PE) pipes intended for drinking water supply.

Bestoplast produces a wide range of HDPE pipes from 25 mm to 630 mm diameter with a nominal pressure of 6 to 16 bar. However, Bestoplast can produce pipes with a nominal pressure of 20 or 25 bar on request.

For drinking water, Bestoplast HDPE pipes are marked by co-extrusion of blue threads.

Bestoplast HDPE pipes for sewage are marked with brown co-extrusion threads.